Konversi Unit

| Inggris (USA) Unit X | Multiply dening | = Unit Metrik | X Multiply dening | = Unit Inggris (USA). | ||

| Pengukuran Linear | in | 25.40 | mm | 0,0394 | in | Pengukuran Linear |

| in | 0,0254 | m | 39.37 | in | ||

| ft | 304.8 | mm | 0,0033 | ft | ||

| ft | 0.3048 | m | 3.281 | ft | ||

| Ukuran Square | ing2 | 645.2 | mm2 | 0,00155 | ing2 | Ukuran Square |

| ing2 | 0,000645 | m2 | 1550.0 | ing2 | ||

| ft2 | 92.903 | mm2 | 0.00001 | ft2 | ||

| ft2 | 0,0929 | m2 | 10.764 | ft2 | ||

| Ukuran Kubik | ft3 | 0,0283 | m3 | 35.31 | ft3 | Ukuran Kubik |

| ft3 | 28.32 | L | 0,0353 | ft3 | ||

| Rate Kacepetan | ft / s | 18.29 | m / min | 0,0547 | ft / s | Rate Kacepetan |

| ft / min | 0.3048 | m / min | 3.281 | ft / min | ||

| Avoirdupois Bobot | lb | 0.4536 | kg | 2.205 | lb | Avoirdupois Bobot |

| lb/ft3 | 16.02 | kg/m3 | 0,0624 | lb/ft3 | ||

| Kapasitas bantalan | lb | 0.4536 | kg | 2.205 | lb | Kapasitas bantalan |

| lb | 4.448 | Newton (N) | 0.225 | lb | ||

| kg | 9.807 | Newton (N) | 0.102 | kg | ||

| lb / ft | 1.488 | kg / m | 0.672 | lb / ft | ||

| lb / ft | 14.59 | N / m | 0,0685 | lb / ft | ||

| kg - m | 9.807 | N / m | 0.102 | kg - m | ||

| Torsi | ing - lb | 11.52 | kg - mm | 0,0868 | ing - lb | Torsi |

| ing - lb | 0.113 | N - m | 8.85 | ing - lb | ||

| kg - mm | 9.81 | N - mm | 0.102 | kg - mm | ||

| Puteran Inersia | ing4 | 416.231 | mm4 | 0.0000024 | ing4 | Puteran Inersia |

| ing4 | 41.62 | cm4 | 0,024 | ing4 | ||

| Tekanan / Stress | lb/ing2 | 0,0007 | kg / mm2 | 1422 | lb/ing2 | Tekanan / Stress |

| lb/ing2 | 0,0703 | kg/cm2 | 14.22 | lb/ing2 | ||

| lb/ing2 | 0,00689 | N / mm2 | 145.0 | lb/ing2 | ||

| lb/ing2 | 0.689 | N / cm2 | 1.450 | lb/ing2 | ||

| lb / ft2 | 4.882 | kg/m2 | 0.205 | lb / ft2 | ||

| lb / ft2 | 47.88 | N / m2 | 0,0209 | lb / ft2 | ||

| daya | HP | 745.7 | watt | 0,00134 | HP | daya |

| ft - lb / min | 0,0226 | watt | 44.25 | ft - lb / min | ||

| Suhu | °F | TC = ( °F - 32 ) / 1.8 | Suhu | |||

Simbol BDEF

| Simbol | Unit | |

| BS | Kekuwatan Tarik Sabuk Konveyor | Kg/M |

| BW | Sabuk Jembar | M |

C. Definisi Simbol

| Simbol | Unit | |

| Ca | Waca Tabel FC | ---- |

| Cb | Waca Tabel FC | ---- |

D. Definisi Simbol

| Simbol | Unit | |

| DS | Rasio defleksi poros | mm |

E. Definisi Simbol

| Simbol | Unit | |

| E | Tingkat Elongasi Poros | Gpa |

F. Definisi Simbol

| Simbol | Unit | |

| FC | Koefisien Gesekan Antarane Sabuk Edge lan Terus Down Strip | ---- |

| FBP | Koefisien Gesekan Antarane Carry Product lan Permukaan Sabuk | ---- |

| FBW | Koefisien Gesekan Bahan Dhukungan Sabuk | ---- |

| FA | Koefisien diubah | ---- |

| FS | Koefisien Kekuwatan Tensile Diowahi | ---- |

| FT | Koefisien Suhu Sabuk Konveyor Diubah | --- |

Simbol saka HILM

| Simbol | Unit | |

| H | Elevasi Conveyor incline altitude. | m |

| HP | Daya kuda | HP |

Definisi Simbol I

| Simbol | Unit | |

| I | Momen Inersia | mm4 |

L Definisi Simbol

| Simbol | Unit | |

| L | Jarak Conveyance (Titik Tengah Saka Poros Penggerak Kanggo Poros Idler) | M |

| LR | Wangsul Way Lurus Run Bagean Length | M |

| LP | Carry Way Straight Run Bagean Panjang | M |

Definisi Simbol M

| Simbol | Unit | |

| M | Tingkat Lapisan Konveyor Spiral | ---- |

| MHP | Daya Kuda Motor | HP |

Simbol PRS

| Simbol | Unit | |

| PP | Produk Akumulasi Ukur Area Persentase Carry Way | ---- |

Definisi Simbol R

| Simbol | Unit | |

| R | Radius Sprocket | mm |

| RO | Radius njaba | mm |

| rpm | Revolusi saben menit | rpm |

Definisi Simbol S

| Simbol | Unit | |

| SB | Interval Antarane Bearing | mm |

| SL | Shaft Total Loading | Kg |

| SW | Bobot Poros | Kg/M |

Simbol TVW

| Simbol | Unit | |

| TA | Unit Sabuk Konveyor Ketegangan Diijini | Kg/M |

| TB | Conveyor Belt Unit Teori Tension | Kg/M |

| TL | Conveyor Belt Unit Catenary kang Sag tension. | Kg/M |

| TN | Ketegangan Bagian | kg/M |

| TS | Torsi | Kg.mm |

| TW | Conveyor Belt Unit Total Tension | Kg/M |

| TWS | Unit Sabuk Konveyor Tipe Khusus Tegangan Total | Kg/M |

V Definisi Simbol

| Simbol | Unit | |

| V | Kacepetan Pangiriman | M/min |

| VS | Kacepetan Teori | M/min |

Definisi Simbol W

| Simbol | Unit | |

| WB | Conveyor Sabuk Unit Bobot | Kg/M2 |

| Wf | Akumulasi Tegangan Gesekan Pengangkutan | Kg/M2 |

| WP | Conveyor Belt Carry Product Unit Bobot |

|

Pusher Lan Bidirectional

Kanggo pusher utawa conveyor bidirectional, tension sabuk bakal luwih dhuwur tinimbang conveyor horisontal biasa;mulane, shafts ing loro ends perlu dianggep minangka drive shafts lan subsumed ing pitungan.Umumé, kira-kira 2,2 kaping faktor pengalaman kanggo entuk ketegangan sabuk total.

FORMULA: TWS = 2,2 TW = 2,2 TB X FA

TWS ing unit iki tegese pitungan tension saka conveyor bidirectional utawa pusher.

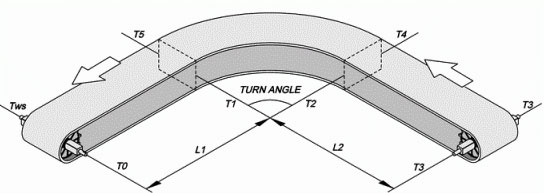

Nguripake Pitungan

TWS pitungan tension saka conveyor ngowahi kanggo ngetung tension akumulasi.Mulane, tension ing saben bagean mbeta bakal mengaruhi Nilai saka total tension.Tegese, tension total dikumpulake saka wiwitan bagean drive kanthi cara bali, ing dalan bali menyang bagean idler, lan banjur ngliwati bagean mbeta menyang bagean drive.

Titik desain ing unit iki yaiku T0 sing ana ing sangisore poros penggerak.Nilai T0 padha karo nol;kita ngetung saben bagean saka T0.Contone, bagean sakcara pisanan ing cara bali saka T0 kanggo T1, lan tegese akumulasi tension saka T1.

T2 minangka tension akumulasi saka posisi ngowahi ing cara bali;ing tembung liyane, iku akumulasi tension saka T0, T1 lan T2.Mangga miturut ilustrasi ing ndhuwur lan nemtokake tension akumulasi saka bagean pungkasan.

FORMULA: TWS = ( T6 )

Total tension saka bagean drive ing cara mbeta.

TWS ing unit iki tegese pitungan tension saka conveyor ngowahi.

FORMULA: T0 = 0

T1 = WB + FBW X LR X WB

Ketegangan catenary sag ing posisi drive.

FORMULA: TN = ( Ca X TN-1 ) + ( Cb X FBW X RO ) X WB

Tension saka bagean ngowahi ing cara bali.

Kanggo nilai Ca lan Cb, mangga deleng Tabel Fc.

T2 = ( Ca X T2-1 ) + ( Cb X FBW X RO ) X WB

TN = ( Ca X T1 ) + ( Cb X FBW X RO ) X WB

FORMULA: TN = TN-1 + FBW X LR X WB

Ketegangan bagean lurus ing cara bali.

T3 = T3-1 + FBW X LR X WB

T3 = T2 + FBW X LR X WB

FORMULA: TN = TN-1 + FBW X LP X ( WB + WP )

Ketegangan saka bagean lurus ing cara mbeta.

T4 = T4-1 + FBW X LP X ( WB + WP )

T4 = T3 + FBW X LP X ( WB + WP )

FORMULA: TN = ( Ca X TN-1 ) + ( Cb X FBW X RO ) X ( WB + WP )

Ketegangan saka bagean ngowahi ing cara mbeta.

Kanggo nilai Ca lan Cb, mangga deleng Tabel Fc.

T5 = ( Ca X T5-1 ) + ( Cb X FBW X RO ) X ( WB + WP )

T5 = ( Ca X T4 ) + ( Cb X FBW X RO ) X ( WB + WP )

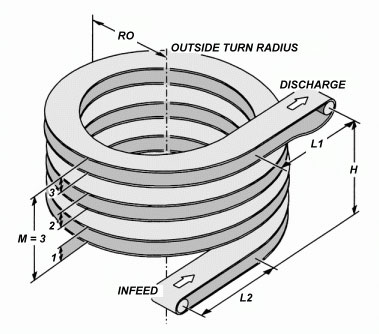

Spiral Conveyor

FORMULA: TWS = TB × FA

TWS ing unit iki tegese pitungan tension conveyor spiral.

FORMULA: TB = [ 2 × RO × M + ( L1 + L2 ) ] ( WP + 2WB ) × FBW + ( WP × H )

FORMULA: TA = BS × FS × FT

Mangga deleng Tabel FT lan Tabel FS.

Tuladha Praktis

Perbandingan TA lan TB, lan petungan liyane sing gegandhengan padha karo jinis conveyor liyane.Ana watesan lan peraturan tartamtu babagan desain lan konstruksi conveyor spiral.Mulane, nalika nglamar HONGSBELT spiral utawa ngowahi sabuk kanggo sistem conveyor spiral, disaranake sampeyan waca manual HONGSBELT Engineering lan kontak karo departemen layanan technical kita kanggo informasi luwih lan rincian.

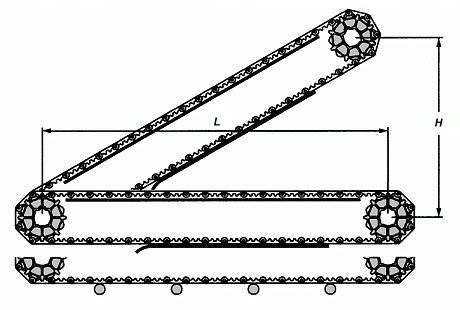

Unit Tension

FORMULA: TB = [ ( WP + 2WB ) X FBW ] XL + ( WP XH )

Yen produk sing nggawa kanthi karakteristik tumpukan, gaya gesekan Wf sing mundhak sajrone transportasi tumpukan kudu dilebokake ing pitungan.

FORMULA: TB = [ ( WP + 2WB ) X FBW + Wf ] XL + ( WP XH )

FORMULA: Wf = WP X FBP X PP

Tension sing diidini

Amarga bahan sabuk sing beda nduweni kekuatan tarik sing beda-beda sing bakal kena pengaruh variasi suhu.Mulane, pitungan saka unit allowable tension TA bisa digunakake kanggo kontras karo sabuk total tension TW.Asil pitungan iki bakal mbantu sampeyan milih pilihan sabuk sing tepat lan cocog karo panjaluk conveyor.Mangga deleng Tabel FS lan Tabel Ts ing menu kiwa.

FORMULA: TA = BS X FS X FT

BS = Kekuwatan Tarik Sabuk Konveyor ( Kg / M )

FS lan FT Waca Tabel FS lan Tabel FT

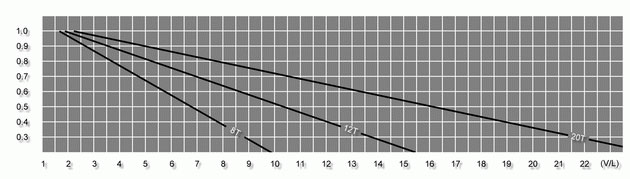

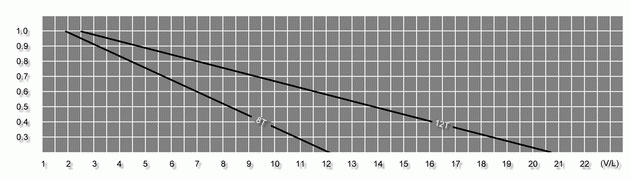

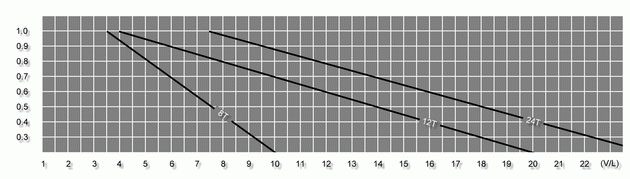

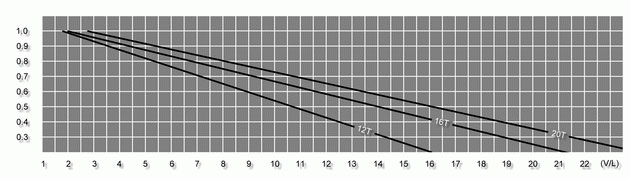

Tabel Fs

Seri HS-100

Seri HS-200

Seri HS-300

Seri HS-400

Seri HS-500

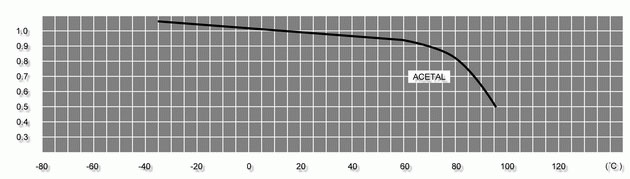

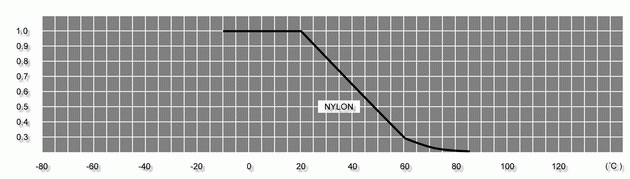

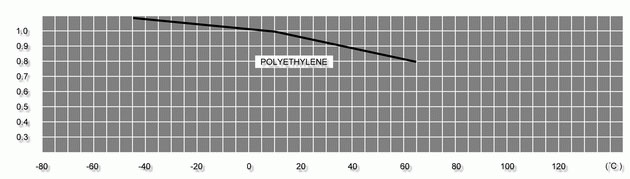

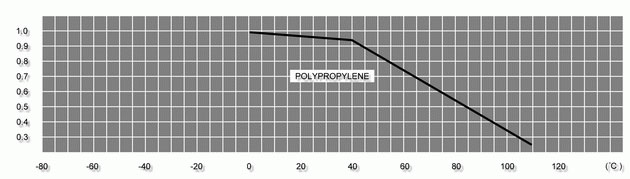

Tabel Ts

Asetal

Nylon

Poliethelin

Polipropilena

Pilihan Shaft

FORMULA: SL = ( TW + SW ) ?BW

mimpin / Idler Shaft Bobot Tabel - SW

| Ukuran Poros | Bobot Poros (Kg/M) | |||

| Baja Karbon | Baja tahan karat | Aluminium Alloy Kab | ||

| Poros persegi | 38 mm | 11.33 | 11.48 | 3.94 |

| 50 mm | 19.62 | 19.87 | 6.82 | |

| Poros Bunder | 30 mm?/FONT> | 5.54 | 5.62 | 1.93 |

| 45mm?/FONT> | 12.48 | 12.64 | 4.34 | |

Deflection saka Drive / Idler Shaft - DS

Tanpa Bearing Penengah

FORMULA:

DS = 5 ?10-4 ( SL ?SB3 / E ?/FONT> I )

Kanthi Bearing Penengah

FORMULA:

DS = 1 ?10-4 ( SL ?SB3 / E ?I )

Elastisitas saka Drive Shaft - E

| Unit: Kg/mm2 | |||

| Bahan | Baja tahan karat | Baja Karbon | Aluminium Alloy Kab |

| Drive Shaft Elastis Rate | 19700 | 21100 | 7000 |

Momen Inersia - I

| Diameter sproket penggerak | Momen inersia poros (mm4) | |

| Poros Square | 38 mm | 174817 |

| 50 mm | 1352750 | |

| Poros Bunder | 30 mm?/FONT> | 40791 |

| 45mm?/FONT> | 326741 | |

Pitungan Torsi Poros Drive - TS

| FORMULA: | TS = TW ?BW ?R |

Kanggo nilai pitungan ing ndhuwur, mangga mbandhingake karo tabel ing ngisor iki kanggo milih poros drive paling apik.Yen torsi poros drive isih kuwat banget, sprocket cilik bisa digunakake kanggo nyuda torsi, lan uga ngirit biaya utama poros lan bantalan.

Nggunakake sprocket sing luwih cilik kanggo pas karo poros drive sing diametere luwih gedhe kanggo nyuda torsi, utawa nggunakake sprocket sing luwih gedhe kanggo pas karo poros drive sing diametere luwih cilik kanggo nambah torsi.

Faktor Torsi Maksimum kanggo Drive Shaft

| Torsi | Bahan | Diameter Jurnal (mm) | ||||||

| 50 | 45 | 40 | 35 | 30 | 25 | 20 | ||

| Kg-mm x 1000 | Baja tahan karat | 180 | 135 | 90 | 68 | 45 | 28 | 12 |

| Baja Karbon | 127 | 85 | 58 | 45 | 28 | 17 | 10 | |

| Aluminium Alloy Kab | -- | -- | -- | 28 | 17 | 12 | 5 | |

Daya kuda

Yen motor drive dipilih kanggo motor reducer gear, rasio tenaga kuda kudu luwih gedhe tinimbang produk sing nggawa lan total gaya tarik sing ditimbulake sajrone sabuk mlaku.

Daya Kuda (HP)

| FORMULA: | = 2,2 × 10-4 × TW × BW × V |

| = 2,2 × 10-4 ( TS × V / R ) | |

| = Watt × 0,00134 |

Watt

| FORMULA: | = ( TW × BW × V ) / ( 6,12 × R ) |

| = ( TS × V ) / ( 6,12 × R ) | |

| = HP × 745.7 |

Tabel FC

| Bahan Rel | Suhu | FC | ||

| Bahan Sabuk | garing | teles | ||

| HDPE / UHMW | -10°C ~ 80°C | PP | 0.10 | 0.10 |

| pe | 0.30 | 0.20 | ||

| Actel | 0.10 | 0.10 | ||

| Nylon | 0.35 | 0.25 | ||

| Asetal | -10°C ~ 100°C | PP | 0.10 | 0.10 |

| pe | 0.10 | 0.10 | ||

| Actel | 0.10 | 0.10 | ||

| Nylon | 0.20 | 0.20 | ||

Mangga kontras bahan ril lan bahan sabuk saka conveyor karo prosedur transportasi ing lingkungan garing utawa udan kanggo entuk nilai FC.

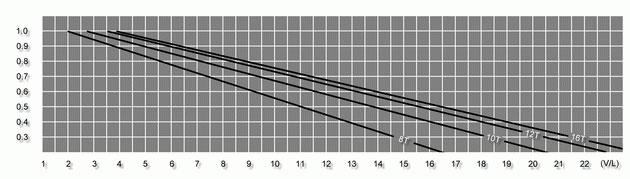

Nilai Ca, Cb

| Conveyor Belt Nguripake Angle | Koefisien Gesekan Antarane Conveyor Belt Edge & Rail Strip | |||||

| FC ≤ 0,15 | FC ≤ 0.2 | FC ≤ 0.3 | ||||

| Ca | Cb | Ca | Cb | Ca | Cb | |

| ≥ 15 ° | 1.04 | 0,023 | 1.05 | 0,021 | 1.00 | 0,023 |

| ≥ 30 ° | 1.08 | 0.044 | 1.11 | 0.046 | 1.17 | 0.048 |

| ≥ 45 ° | 1.13 | 0.073 | 1.17 | 0.071 | 1.27 | 0.075 |

| ≥ 60 ° | 1.17 | 0.094 | 1.23 | 0.096 | 1.37 | 0.10 |

| ≥ 90 ° | 1.27 | 0.15 | 1.37 | 0.15 | 1.6 | 0.17 |

| ≥ 180 ° | 1.6 | 0.33 | 1.88 | 0.37 | 2.57 | 0.44 |

Sawise njupuk nilai FC saka Tabel FC, please kontras karo amba sudhut mlengkung saka conveyor, lan sampeyan bisa njaluk nilai Ca lan nilai Cb.